As more and more companies continue to embrace the Internet of Things (IoT) to make their operations more efficient, one of the biggest challenges is seamless, secure communication between devices spread across wide networks and the complexity of integrating industrial systems with web-based technologies often leaves organizations grappling with unreliable or inefficient solutions.

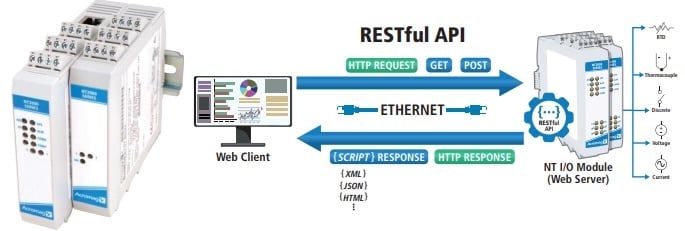

Acromag’s BusWorks NT remote I/O Modules will feature RESTful API to aid in the development of web-based services. Image used courtesy of Acromag

Acromag’s BusWorks NT Series remote I/O modules now offer an effective solution for integrators; with the addition of a RESTful API, they can now include simple, secure communication between devices over a standard Ethernet connection. By using HTTP POST and GET requests, the RESTful API allows seamless web service integration for remote monitoring and control, making it easier for industries to manage and automate their systems in real-time. Whether it's energy management, predictive maintenance, or actuator control, the NT Series offers a robust and scalable solution.

What will RESTful API add to your systems?

The introduction of the RESTful API in Acromag’s NT Series modules can help machine builders develop how industrial data is managed. RESTful APIs have become popular in web development due to their simplicity and lightweight nature, relying on the universal HTTP protocol. This allows developers of industrial applications to use common programming languages like XML, JSON, or HTML to build IoT interfaces that are fast, flexible, and cost-effective and prevent the need for third-party tools to complete the integration.

Acromag’s RESTful API provides fast data transfer while consuming less bandwidth. Image used courtesy of Acromag

The NT Series is able to connect remotely via Ethernet using dual RJ45 ports, which gives system controllers access to I/O data from anywhere, making it ideal for remote data acquisition, status monitoring, or controlling field devices like sensors and actuators. The system supports up to 16 input or output channels per I/O module, and up to three expansion modules can be added to interface an additional 48 channels. This scalability means the NT Series can easily grow to meet the evolving needs of industrial manufacturing.

What Communication Protocols Are Available?

Acromag’s NT Series modules are designed to support a wide range of industrial protocols, which makes them even more versatile. In addition to the RESTful API, the modules support other industry-standard interfaces, such as OPC UA, MQTT, Modbus TCP, Ethernet/IP, and PROFINET. This compatibility allows businesses to integrate the BusWorks NT Series I/O modules into their existing systems without the need for expensive and time-consuming overhauls. Furthermore, Acromag’s I/O modules will now feature Acromag’s i2o peer-to-peer communication technology. This communication feature enables direct data transfer between devices without requiring a host or master system, which somewhat adds a layer of flexibility and can open up possibilities for advanced applications in automation and industrial networking.

Acromag’s NT Series, with its RESTful API, offers industries a more efficient way to manage IoT devices and systems, simplifying the communication between remote modules. With seamless integration, scalability, and support for various industrial protocols, this solution addresses the need for more reliable and cost-effective industrial automation systems.