Turck, a well - known name in the field of industrial automation, has made a significant stride with the release of its “Smart” IP67 power supplies equipped with an IO - Link interface. This innovation is set to revolutionize the way power is managed and monitored in industrial environments.

In the past, traditional power supplies were often limited in their functionality. They simply provided electrical power to various devices in an industrial setting. However, with the increasing demand for more intelligent and efficient systems, there was a clear need for a new generation of power supplies. Turck recognized this gap in the market and decided to develop a solution that would not only provide reliable power but also offer advanced monitoring and control capabilities.

The IP67 rating of these power supplies is a crucial feature. In industrial environments, equipment is often exposed to harsh conditions such as dust, water, and extreme temperatures. The IP67 rating means that these power supplies are dust - tight and can withstand immersion in water up to a certain depth. This makes them suitable for use in a wide range of industries, including manufacturing, food and beverage, and automotive. For example, in a food processing plant, where hygiene is of utmost importance and equipment is frequently washed down, the IP67 - rated power supplies can ensure continuous operation without being damaged by water or debris.

The addition of the IO - Link interface is what truly sets these power supplies apart. IO - Link is an open, standardized communication protocol that allows for seamless integration of sensors and actuators into industrial networks. With the IO - Link interface, the “Smart” IP67 power supplies can communicate real - time data about their status, such as output voltage, current, and temperature. This data can be transmitted to a central control system, enabling operators to monitor the power supplies remotely and make informed decisions.

One of the key advantages of this real - time monitoring is the ability to detect potential problems before they lead to system failures. For instance, if the output voltage of a power supply starts to deviate from the normal range, the control system can receive an alert. Operators can then take proactive measures, such as adjusting the power settings or scheng maintenance, to prevent costly downtime. This predictive maintenance approach can significantly improve the overall efficiency and reliability of industrial systems.

Moreover, the IO - Link interface also allows for configuration and parameterization of the power supplies. Operators can use a software tool to set various parameters, such as output voltage levels and over - current protection thresholds. This flexibility makes it easier to adapt the power supplies to different applications and requirements. For example, in a complex manufacturing process where different devices require different power levels, the power supplies can be easily configured to meet these specific needs.

Another benefit of the “Smart” IP67 power supplies is their energy efficiency. By continuously monitoring the power consumption and adjusting the output accordingly, these power supplies can optimize energy usage. This not only reduces energy costs but also contributes to a more sustainable industrial operation. In today's world, where environmental concerns are on the rise, energy - efficient solutions like these are highly desirable.

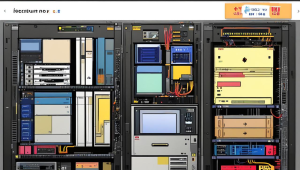

In addition to their technical advantages, Turck's “Smart” IP67 power supplies are also designed with ease of installation and use in mind. They have a compact and modular design, which makes them easy to integrate into existing systems. The clear and intuitive user interface further simplifies the operation and configuration process. Even operators with limited technical knowledge can quickly learn how to use these power supplies effectively.

The release of Turck's “Smart” IP67 power supplies with an IO - Link interface is a game - changer in the industrial automation market. These power supplies offer a combination of robustness, intelligence, and energy efficiency that was previously unavailable. As industries continue to evolve and demand more advanced solutions, products like these will play a crucial role in driving the next wave of industrial innovation. Whether it's improving system reliability, reducing energy costs, or enabling more efficient operation, Turck's “Smart” power supplies are well - positioned to meet the challenges of modern industrial environments.

In conclusion, Turck has once again demonstrated its commitment to providing cutting - edge solutions for the industrial sector. The “Smart” IP67 power supplies with IO - Link interface are a testament to the company's innovative spirit and its ability to address the evolving needs of its customers. As more and more industries adopt these advanced power supplies, we can expect to see a significant improvement in the performance and efficiency of industrial systems around the world.